|

|

|

|

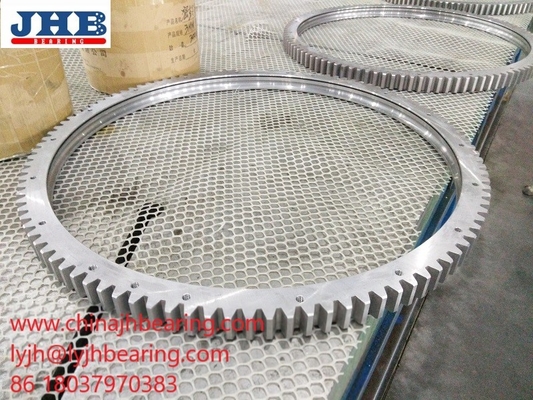

E.1604.50.10.D.1-RV bearing with teeth matched pinion 1208x1604x128mm for crane machine

Product Details:

Payment & Shipping Terms:

|

| Precision Rating: | P5 P6 P0 | Seals Type: | With Seal |

|---|---|---|---|

| Number Of Row: | Single Row | Outer Dia: | 1604mm |

| Inner Dia: | 1208mm | Height: | 128mm |

E.1604.50.10.D.1-RV bearing with teeth matched pinion 1208x1604x128mm for crane machine

Name: E.1604.50.10.D.1-RV bearing is the TG Series E.30-45-50.D-R product., E.1604.50.10.D.1-RV slewing bearing, E.1604.50.10.D.1-RV slewing ring, E.1604.50.10.D.1-RV turntable bearing, E.1604.50.10.D.1-RV slewing bearing supplier

• Structure:Crossed cylindrical roller slewing bearing with exteral gear

• Brand Name: JHB or OEM Required

• Bore Size: 1208 mm metric size

• Outside Diameter:1604 mm metric size

• Height:128 mm metric size

• Teeth Options: with teeth/gear

• Seals Type: double lip seal

• Lubrication:grease

• Bearing mark: Brand+ E.1604.50.10.D.1-RV Or your requirement

• Place of Origin: LuoYang, China (Mainland)

• Delivery Time: 20-30 days

• Sample:available

• Material: 50Mn,42CrMo

• The package: Inside packaging: plastic film + kraft paper + blue tape; Outside packaging: standard export free-fumigation wooden case

• Payment: T/T or L/C

E.1604.50.10.D.1-RV slewing bearing Specifications

1. High precision: P5,P6,P0

2. Low noise

3. Long serive life

4. short delivery time

5. OEM service provided

6. Processing with supplied drawings

|

Description |

E.1604.50.10.D.1-RV slewing bearing |

|

Outside and Inside diameter tolerances |

in accordance with ISO2768-m |

|

Dimension(ODXIDXH) |

1604x1208x128 mm |

|

Outer diameter(OD) |

1604mm |

|

Inner diameter(ID) |

1208mm |

|

Width/Height/(H) |

128mm |

|

Fz nor |

55KN |

|

Fz max |

110 KN |

|

Gear data |

With external gear/teeth |

|

Gear teech P |

1570mm |

|

Gear teeth m |

10 |

|

Gear teeth Z |

157 |

|

weight |

606 kgs |

|

Contact us |

www.chinajhbearing.com www.lyjhbearing.com E-mail: lyjh@lyjhbearing.com

|

The bearing E.1604.50.10.D.1-RV Reference pictures as following:

![]()

![]()

JinHang Precision Bearing mainly export high quantities E.1604.50.10.D.1-RV Slewing Bearing and relative products, we had owned advanced CNC Machine to manufacture them.From the forging material to Bearing assembly ,we had performance ISO Quality system. Every process, we had make the note and keep them. Also, our engineer can supply the technolgoy communication and guide. If you want to know the E.1476.45.15.D.1-RV Slewing ring more, Please contact us as follow,Thanks for your trust!

7.1 Rolling elements: self-machined or steel ball rollers from fixed-point manufacturers. The accuracy grade shall meet the requirements of the drawings. The rolling elements differ from each other by less than 5%. Surface magnetic particle inspection and ultrasonic inspection shall be performed before bearing assembly, and an inspection report shall be issued.

7.2 Retainer: The retainer produced by the fixed-point manufacturer is adopted. The materials are in accordance with the requirements of the drawing. Strict inspection is required before the assembly and use, and a test report is issued.

7.3 Sealing ring: The sealing strip produced by the fixed-point manufacturer is used. Strict inspection is required before assembly, and an inspection record is issued. 8) Assembly

8.1 Preparation of clearance: After the grinding process, a trial assembly is required to determine the preliminary clearance. Based on the calculated data and the trial installation clearance, the final grinding process is performed to assign the final drawing to specify the clearance.

8.2 Parts inspection: After the clearance preparation is completed, the final parts inspection shall be carried out and corresponding records shall be made. 8.3 Demagnetize, clean, pack and issue a certificate of conformity.

Delivery documents—In order to enable users to better understand the technical parameters such as the inherent quality of the rotary bearing and the source of materials, the following technical information is provided:

7) (1) Turntable bearing certificate.

(2) Installation and operation manual of turntable bearing

(3) certificate of bearing material (material book)

(4) Rolling body flaw detection report

(5) Bearing heat treatment certificate

![]()

![]()

-

VA160235N Four Point Contact Ball Bearing With Teeth 318.6*234*40mm

-

Slewing Bearing 16295001 Internal Teeth For Log Loaders Fellers Machine 730*496*85.7mm

-

What'S The Slewing Bearing? Slewing Bearing Structure

-

RKS.322300101001 crossed roller Slewing bearing with external gear 980x1296x114 mm

-

E.1390.30.15.D.1-R slewing bearing 1390x1115x105 mm for plastic and rubber machine

-

Port hoisting machine use RKS.162.16.1314 Slewing bearing with gear 1182x1399x68 mm