|

|

|

|

E.1390.30.15.D.1-R slewing bearing 1390x1115x105 mm for plastic and rubber machine

Product Details:

Payment & Shipping Terms:

|

| Precision Rating: | P5 P6 P0 | Seals Type: | With Seal |

|---|---|---|---|

| Number Of Row: | Single Row | Outer Dia: | 1390mm |

| Inner Dia: | 1115mm | Height: | 105mm |

E.1390.30.15.D.1-R slewing bearing 1390x1115x105 mm for plastic and rubber machine

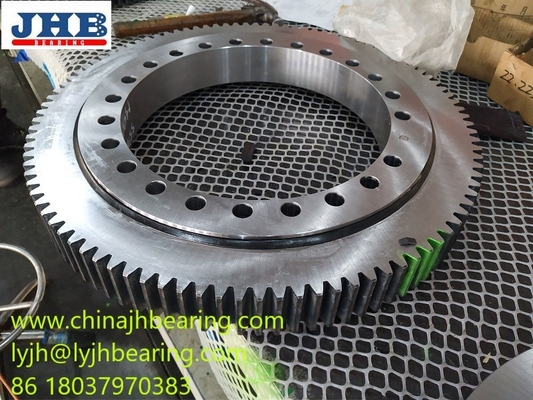

Name: E.1390.30.15.D.1-R bearing is the TG Series E.30-45-50.D-R product., E.1390.30.15.D.1-R slewing bearing, E.1390.30.15.D.1-R slewing ring, E.1390.30.15.D.1-R turntable bearing, E.1390.30.15.D.1-R slewing bearing supplier

• Structure:Crossed cylindrical roller slewing bearing with exteral gear

• Brand Name: JHB or OEM Required

• Bore Size: 1115 mm metric size

• Outside Diameter:1390 mm metric size

• Height:105 mm metric size

• Teeth Options: with teeth/gear

• Seals Type: double lip seal

• Lubrication:grease

• Bearing mark: Brand+ E.1390.30.15.D.1-R Or your requirement

• Place of Origin: LuoYang, China (Mainland)

• Delivery Time: 20-30 days

• Sample:available

• Material: 50Mn,42CrMo

• The package: Inside packaging: plastic film + kraft paper + blue tape; Outside packaging: standard export free-fumigation wooden case

• Payment: T/T or L/C

E.1390.30.15.D.1-R slewing bearing Specifications

1. High precision: P5,P6,P0

2. Low noise

3. Long serive life

4. short delivery time

5. OEM service provided

6. Processing with supplied drawings

|

Description |

E.1390.30.15.D.1-R slewing bearing |

|

Outside and Inside diameter tolerances |

in accordance with ISO2768-m |

|

Dimension(ODXIDXH) |

1390x1115x105 mm |

|

Outer diameter(OD) |

1390mm |

|

Inner diameter(ID) |

1115mm |

|

Width/Height/(H) |

105mm |

|

Fz nor |

82KN |

|

Fz max |

164 KN |

|

Gear data |

With external gear/teeth |

|

Gear teech P |

1368mm |

|

Gear teeth m |

12 |

|

Gear teeth Z |

114 |

|

weight |

329 kgs |

|

Contact us |

www.chinajhbearing.com www.lyjhbearing.com E-mail: lyjh@lyjhbearing.com

|

The bearing E.1390.30.15.D.1-R Reference pictures as following:

![]()

![]()

![]()

![]()

Forging process:

The blanks of bearing rings are mainly made of rods and tubes, while the forging process is only applicable to rods. However, forgings are the most used blank materials in bearing manufacturing, and are suitable for large and medium-sized bearings. Forging can be divided into hot forging, cold forging and warm forging. Hot forging refers to processing above the re-crystallization temperature of the billet metal, warm forging is forging at a temperature not exceeding the re-crystallization temperature, and cold forging refers to forging at normal temperature.

The purpose of ferrule forging: 1. Through forging, obtain a blank with a size similar to the product, improve the utilization of metal materials, reduce the amount of machining, and reduce costs. 2. Forging can eliminate the internal defects of the metal, improve the structure, and thus increase the service life of the bearing.

General process of forging:

Bar material ,inspection, heating, blanking, secondary heating, forging, rolling,cooling, annealing, cleaning

Rough turning: Rough turning is performed according to the drawing of the turning process, and the cutting speed and cutting amount are strictly implemented according to the technical regulations (the general cutting speed is 5 rpm. The cutting amount is 10mm ~ 12mm).

2.2 Rough turning aging: After the rough turning of bearing parts is completed, three-point support and flat laying is not allowed (stacking is not allowed), and the precision turning processing can be performed after the aging time is not less than 48 hours.

2.3 Fine turning bearing parts When finishing turning, the cutting speed is 6 to 8 revolutions per minute, and the cutting amount is 0.3 to 0.5 mm.

2.4 Precision turning: In order to prevent the parts from deforming when the bearing parts are finally finished, the parts must be loosened to make the parts in a non-stressed state. The turning speed is 8 revolutions per minute and the cutting amount is 0.2 mm.

2.5 Cross and three-row roller slewing bearing inner ring special process: To prevent cross and three-row roller slewing bearing inner ring from deforming after heat treatment. The turning process must be performed in pairs, that is, the raceway is back-to-back processing. No cutting is performed before heat treatment, and cutting is performed after heating.

2.6 Finished car after heating: After the inner and outer rings of the bearing are heat-treated, the finished car turning process is carried out, and the technical procedures are the same as 2.3 and 2.43)

-

VA160235N Four Point Contact Ball Bearing With Teeth 318.6*234*40mm

-

Slewing Bearing 16295001 Internal Teeth For Log Loaders Fellers Machine 730*496*85.7mm

-

What'S The Slewing Bearing? Slewing Bearing Structure

-

RKS.322300101001 crossed roller Slewing bearing with external gear 980x1296x114 mm

-

E.1604.50.10.D.1-RV bearing with teeth matched pinion 1208x1604x128mm for crane machine

-

Port hoisting machine use RKS.162.16.1314 Slewing bearing with gear 1182x1399x68 mm