|

|

|

|

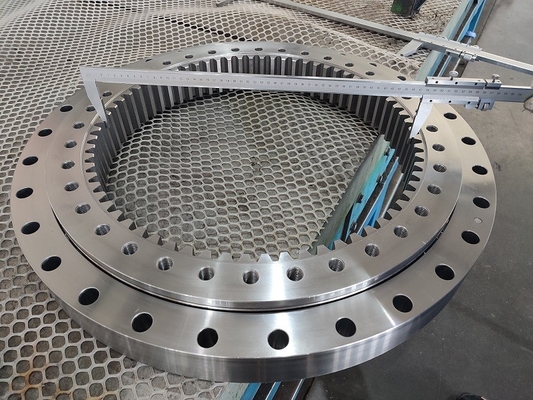

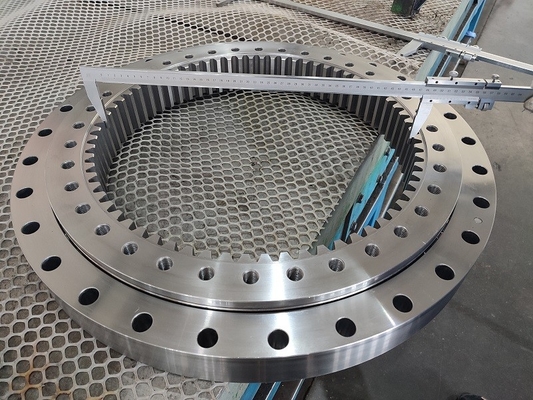

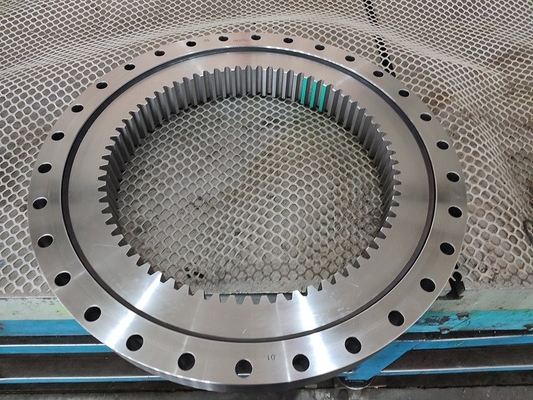

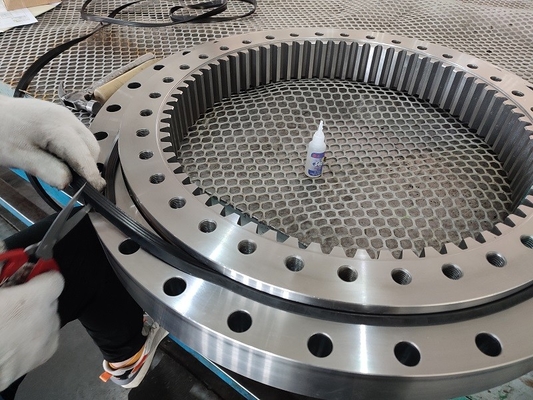

Slewing Bearing 16295001 Internal Teeth For Log Loaders Fellers Machine 730*496*85.7mm

Product Details:

Payment & Shipping Terms:

|

| Precision Rating: | P4 P5 | Seals Type: | No Seal |

|---|---|---|---|

| Number Of Row: | Single Row | Outer Dia: | 730mm |

| Inner Dia: | 496mm | Height: | 85.7mm |

Slewing Bearing 16295001 Internal Teeth For Log Loaders Fellers Machine 730*496*85.7mm

The internal configuration bearing 16295001 consists of deep groove gothic arch raceways and maximum ball complement. This results in a four-point contact design which provides exceptional moment, thrust, and radial load capacities. Integral seals are provided to assist in the exclusion of contaminants.The bearing 16295001 with the boundary size 730*496*85.7mm

| Product Name: | Slewing bearing turntable bearing slewing ring swivel bearing |

| Model: | 16295001 Kaydon bearing code |

| Old model: | 16295001 |

| Price: | USD200 to 2000 |

| Min qty: | 4PCS |

| Production Capacity: | 200000PCS/Month |

| Payment term: | T/T,WU,LC |

| Delivery time: | 30-45 days |

| Shipping Ways: | By sea by air FedEx/DHL,UPS available |

| Port: | Shanghai /Qingdao seaport |

| Transport Package: | Carton+Wooden case |

| Country of Origin: | China |

| Keywords: | 16295001 bearing, 16295001 bearings, 730*496*85.7mm ball bearing,16295001china bearing factory |

| Structure: | Light series four-point contact ball slewing bearings with an internal gear |

| Number of Rows: | single rows |

| Units: | mm |

| Inside Diameter: | 304mm |

| Outside Diameter: | 505mm |

| Thickness/Width: | 56mm |

| Boundary: | Metric size 730*496*85.7mm,inch size:28.74x19.543x3.38 |

| HS Code: | 8482800000 slewing bearing |

| Teeth parameter | d0=508mm m=5 z=70 |

| Teeth structure | internal teeth |

| Brand: | JHB or OEM |

| Weight:(kgs) | 75KGS |

| Clearance: | C1 C2 C0 C3 C4 |

| Bearing Material: | Steel Chrome GCr15 GCr15SiMn |

| Ball brand | LYC Brand |

| Bearing material | 50Mn 42CrMo available |

| Service: | Offer assembly drawing,technology service |

| Quality Control: | ISO9001:2008 Quality certificate |

| Application: | Aerial Hydraulic Platforms • Antennas • Arc Furnaces • Band Conveyor • Blast Furnace Gas Cover • Casting Equipment • Construction Machinery • Container Spreader • Crane Wheel Bogie • Deck Cranes • EDS Scanner Excavators • Fifth Wheel / Trailer Bogie • Gantry Cranes • Ladle Turrets • Machine Tools • Mechanical Engineering Medical Equipment • Mixer • Mobile Cranes • Mooring station • Off shore Crane • Packaging or Bottling Equipment Paddle Wheel Bearings • Ship Loader/Unloader • Solar Energy Plants • Special Sales • Stackers/Reclaimers Swivel Bearings • Telescopes • Thruster • Tidal Energy Plants • Tower Cranes • Truck Mounted Cranes • Tunnel Boring Machines • Water Treatment Equipment • Wind Energy Plants |

![]()

![]()

![]()

![]()

Slewing bearing is one of our main products.

1. four point contact ball slewing bearing (no gear, external gear, internal gear);

2. two row ball slewing bearing (no gear, external gear, internal gear);

3. crossed cylindrical roller slewing bearing;(no gear, external gear, internal gear);

4. three row cylindrical roller slewing bearing;(no gear, external gear, internal gear);

5. crossed tapered roller slewing bearing; (no gear, external gear, internal gear);

6. ball and roller combined slewing bearing.(no gear, external gear, internal gear);

Bearing Parts

Steel ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Material

Cage: include integral cage, segment cage and spacer-type cage. We use 20# steel or copper for integral and segment cages, PA 1010 resin or QA110-3-105 albronze for spacer-type cages.

Seals:uses NBR or VITON, few felted wool.

Bearing material:

Forging process:

The blanks of bearing rings are mainly made of rods and tubes, while the forging process is only applicable to rods. However, forgings are the most used blank materials in bearing manufacturing, and are suitable for large and medium-sized bearings. Forging can be divided into hot forging, cold forging and warm forging. Hot forging refers to processing above the re-crystallization temperature of the billet metal, warm forging is forging at a temperature not exceeding the re-crystallization temperature, and cold forging refers to forging at normal temperature.

The purpose of ferrule forging: 1. Through forging, obtain a blank with a size similar to the product, improve the utilization of metal materials, reduce the amount of machining, and reduce costs. 2. Forging can eliminate the internal defects of the metal, improve the structure, and thus increase the service life of the bearing.

General process of forging:

Bar material ,inspection, heating, blanking, secondary heating, forging, rolling,cooling, annealing, cleaning

Slewing bearings perform extremely well in a variety of applications such as:

• access platforms

• bucket wheel excavators

• conveyor booms

• cranes of all types

• small, medium and large excavators

• indexing tables

• ladle turrets

• offshore applications

• robots

• railway bogies

• rotary platforms

• solar mirrors

• tunnel boring machines

• wind turbines

![]()

-

VA160235N Four Point Contact Ball Bearing With Teeth 318.6*234*40mm

-

What'S The Slewing Bearing? Slewing Bearing Structure

-

RKS.322300101001 crossed roller Slewing bearing with external gear 980x1296x114 mm

-

E.1604.50.10.D.1-RV bearing with teeth matched pinion 1208x1604x128mm for crane machine

-

E.1390.30.15.D.1-R slewing bearing 1390x1115x105 mm for plastic and rubber machine

-

Port hoisting machine use RKS.162.16.1314 Slewing bearing with gear 1182x1399x68 mm