|

|

|

|

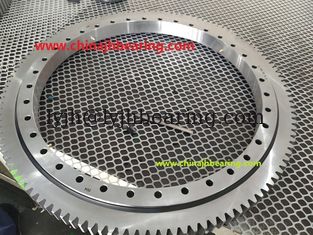

Slewing ball bearing E 750.20.00.B with size 742.3x572x56mm with external teeth

Product Details:

Payment & Shipping Terms:

|

| Teeth: | External Teeth | Seals Type: | Double Seal |

|---|---|---|---|

| Number Of Row: | Single Row | Ring Material: | 42CrMo 50Mn |

| Pulg: | Yes | Lubrication: | Grease |

Slewing ball bearing E750.20.00.B with size 742.3x572x56mm with external teeth

E 750.20.00.B slewing bearing with external teeth belongs to thin section bearing, the outer ring and inner ring height only 56mm,

E750.20.00.B Slewing bearing consist of outer ring,inner ring,ball and seal.The outer ring with teeth. It is composed of two seat rings. It has compact structure, light weight, and four-point contact between steel ball and arc raceway. It can bear axial force, radial force and overturning moment at the same time. The construction machinery of rotary conveyor, welding manipulator, small and medium-sized crane and excavator can be selected.

E 750.20.00.B slewing bearing size details as following :

| Bearing type | E 750.20.00.B |

| Size | 742.3x572x56mm |

| Outer dia | 742.3mm |

| Inner dia | 572mm |

| Height | 56mm |

| Rolling Body: | Ball |

| Outer ring material | 50Mn,42CrMo |

| Inner ring material | 50Mn,42CrMo |

| Ball material | GCr15 |

| Sealing Type | Double seal |

E 750.20.00.B slewing bearing actual picture, Please reference the picture:

![]()

![]()

E 750.20.00.B slewing bearing Product process:

Forging process:

The blanks of bearing rings are mainly made of rods and tubes, while the forging process is only applicable to rods. However, forgings are the most used blank materials in bearing manufacturing, and are suitable for large and medium-sized bearings. Forging can be divided into hot forging, cold forging and warm forging. Hot forging refers to processing above the re-crystallization temperature of the billet metal, warm forging is forging at a temperature not exceeding the re-crystallization temperature, and cold forging refers to forging at normal temperature.

The purpose of ferrule forging: 1. Through forging, obtain a blank with a size similar to the product, improve the utilization of metal materials, reduce the amount of machining, and reduce costs. 2. Forging can eliminate the internal defects of the metal, improve the structure, and thus increase the service life of the bearing.

General process of forging:

Bar material ,inspection, heating, blanking, secondary heating, forging, rolling,cooling, annealing, cleaning.

Rough turning: Rough turning is performed according to the drawing of the turning process, and the cutting speed and cutting amount are strictly implemented according to the technical regulations (the general cutting speed is 5 rpm. The cutting amount is 10mm ~ 12mm).

2.2 Rough turning aging: After the rough turning of bearing parts is completed, three-point support and flat laying is not allowed (stacking is not allowed), and the precision turning processing can be performed after the aging time is not less than 48 hours.

2.3 Fine turning bearing parts When finishing turning, the cutting speed is 6 to 8 revolutions per minute, and the cutting amount is 0.3 to 0.5 mm.

2.4 Precision turning: In order to prevent the parts from deforming when the bearing parts are finally finished, the parts must be loosened to make the parts in a non-stressed state. The turning speed is 8 revolutions per minute and the cutting amount is 0.2 mm.

-

Turntable Bearings RKS.061.25.1204 Dimension 1338X1119X68mm

-

Turntable Roller Bearing Ring With Gear Teeth RKS.162.14.0744

-

Slewing Ring Bearing RKS.060.20.0944 For Swivel Turntable

-

Slewing Ring Fa-00r3 Internal Gear Teeth Factory 1166X985.6X54mm

-

Four Point Contact Ball Bearing E.1200.20.00.C Size 1198.4X984X56mm

-

Four Point Contact Ball Bearing Factory E787/760G2 950*760*80mm